POLIMAXX ABS เป็นพลาสติกวิศวกรรมที่ประกอบจากมอนอเมอร์ 3 ตัว คือ Acrylonitrile, Butadiene และ Styrene ที่มีคุณสมบัติให้ความสมดุลทั้งความแข็งและความเหนียว ความสามารถทนต่อแรงกระแทกที่สูง คงสภาพรูปร่างได้ดี ชิ้นงานมันเงา ทนต่อแรงเสียดสีและการขีดข่วน ABS จึงนิยมนำไปผลิตชิ้นผลิตวัสดุโครงสร้างภายนอกของเครื่องใช้ไฟฟ้า-อิเล็กทรอนิกส์ ชิ้นส่วนยานยนต์ ของเล่น และอุตสาหกรรมอื่น ๆ

รายละเอียดเพิ่มเติม

POLIMAXX ABS Compound เป็นอีกทางเลือกหนึ่งของ POLIMAXX Solution ที่นำเสนอความสะดวกในการใช้งานให้กับลูกค้าด้วยการทำ ABS Compound ไม่ว่าจะเป็นการทำ Color Matching หรือการผสมสารเติมแต่ง (Fibre-reinforced) เพื่อปรับปรุงผลิตภัณฑ์ ABS ให้ตรงตามความต้องการของลูกค้า

รายละเอียดเพิ่มเติม

POLIMAXX ABS Powder เป็นทางเลือกใหม่ที่ IRPC ได้เพิ่มทางเลือกให้ลูกค้าได้ประโยชน์สูงสุด “Powder ABS” เหมาะสำหรับผู้ผลิตที่ต้องการคุณสมบัติการกระจายตัวของโพลิเมอร์ที่ดีกว่าการใช้เม็ดพลาสติกเดิม สามารถนำไปใช้กับเม็ดพลาสติก PVC, PC หรือ PC/ABS ซึ่งจะช่วยเพิ่มคุณสมบัติที่ได้หลากหลายคือ เพิ่มคุณสมบัติการทนต่อแรงกระแทก เพิ่มคุณสมบัติในเรื่องการทนต่อความร้อน

รายละเอียดเพิ่มเติม

POLIMAXX Acetylene Black ผลิตภัณฑ์อะเชทีลีน แบล็ค มีคุณสมบัติเด่น ในเรื่องความบริสุทธิ์ และการนำไฟฟ้าสูง นิยมนำไปใช้ ในการผลิตถ่านไฟฉายผลิตภัณฑ์โพลีเมอร์และยาง

รายละเอียดเพิ่มเติม

POLIMAXX AS/SAN เป็นเม็ดพลาสติกที่ถูกพัฒนาขึ้นเพื่อให้มีคุณลักษณะเชิงกลที่ทนต่อความร้อน สารเคมีและสภาพแวดล้อม มีความเหนียวกว่าพอลิสไตรีนเกรดทั่วไป โดยยังคงคุณสมบัติของความแข็งและโปร่งใส นิยมนำ AS/SAN ไปผลิตชิ้นส่วนเครื่องใช้ไฟฟ้า บรรจุภัณฑ์สำหรับเครื่องสำอาง ไฟแช็ค และเครื่องใช้ในครัวเรือนที่มีคุณภาพสูง เช่น โถปั่นอาหาร เป็นต้น

รายละเอียดเพิ่มเติม

POLIMAXX EPS เป็นเม็ดพลาสติกที่ทนต่อแรงกระแทก มีความเบา สามารถเก็บเสียงได้ดี จึงนิยมนำไปผลิตโฟมฉนวนกันความร้อน โฟมกันกระแทก ลังปลา นอกจากนี้ยังใช้แพร่หลายในงานก่อสร้าง เพื่อเป็นวัสดุกันความร้อนเช่นกัน

รายละเอียดเพิ่มเติม

POLIMAXX HDPE พอลิเอทิลีนความหนาแน่นสูงมีลักษณะทึบแสง ผลิตภัณฑ์มีความต้านทานแรงดึงสูง ทนต่อแรงกระแทก และทนต่อสารเคมีสูงม มักนำไปใช้กันอย่างแพร่หลายสำหรับการผลิตถังและภาชนะ บรรจุภัณฑ์อุตสาหกรรม เช่น ลังผลไม้ ลังเบียร์ เป็นต้น

รายละเอียดเพิ่มเติม

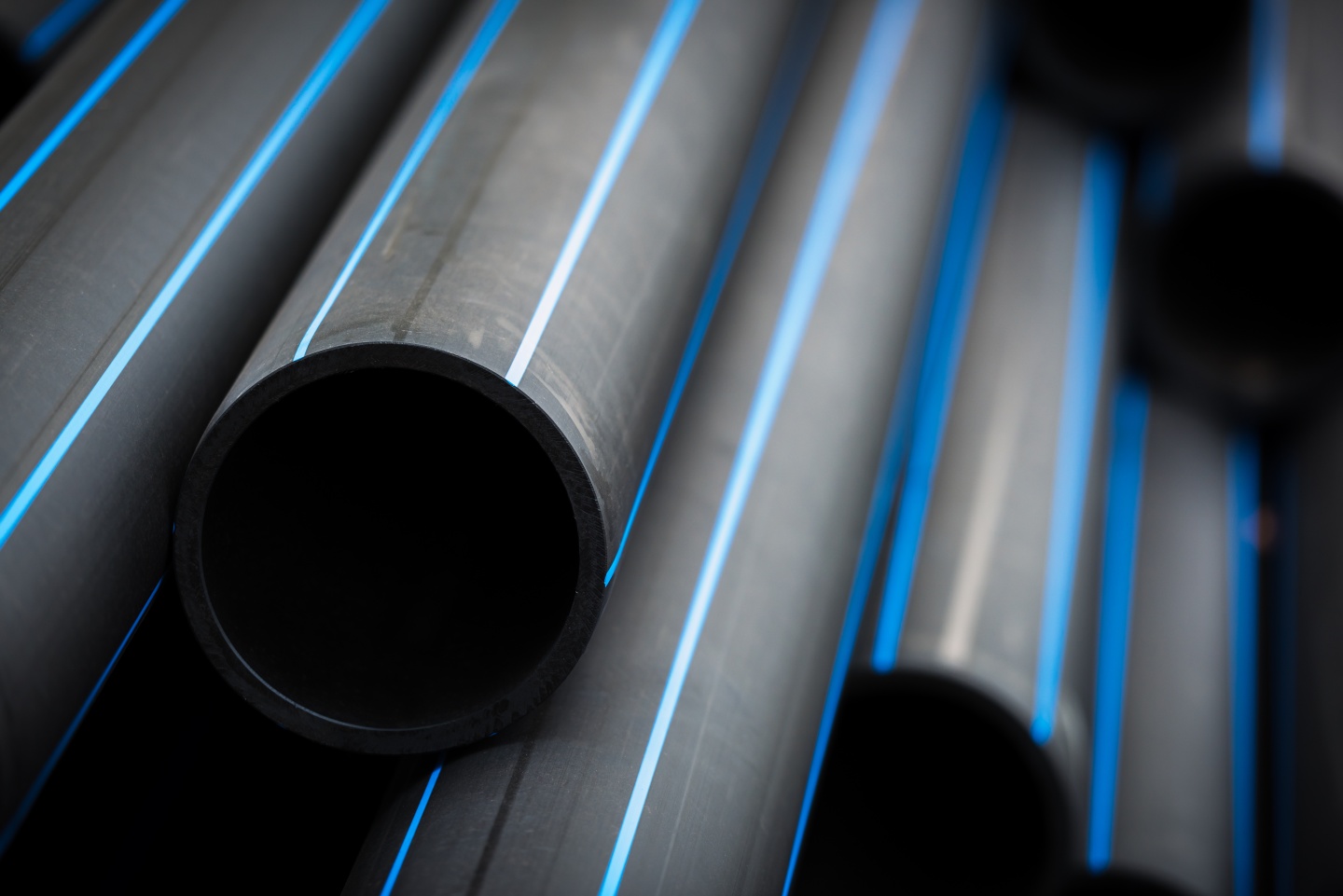

POLIMAXX PE Compound เป็นอีกทางเลือกหนึ่งของ POLIMAXX Solution ที่นำเสนอความสะดวกในการใช้งานให้กับลูกค้าด้วยการทำ PE Compound เช่น คอมพาวน์เกรดท่อพอลิเอทิลีนชนิดที่มีความหนาแน่นสูง ซึ่งมีคุณสมบัติทำให้ท่อมีความแข็งแรงทนทาน สามารถทนความดัน ทนต่อการกัดกร่อนของสารเคมีมีอายุการใช้งานที่ยาวนาน ผลิตภัณฑ์ของเราสามารถนำไปใช้ในการผลิตท่อน้ำในรูปต่างๆ เช่น ท่อน้ำดื่ม ท่อส่งน้ำชลประทาน ท่อส่งน้ำใต้ทะเล เป็นต้น และยังมีเปลือกนอกหุ้มสายไฟ ทุ่นโซลาร์ลอยน้ำ

รายละเอียดเพิ่มเติม

POLIMAXX PE WAX พอลิเอทิลีนชนิดหนึ่งที่มีลักษณะคล้ายขี้ผึ้ง มีคุณสมบัติเพิ่มความมันเงางามให้พื้นผิววัสดุ เพิ่มความคงทนต่อรอยขีดข่วน เพิ่มประสิทธิภาพในงานคอมพาวนด์นอกจากนี้ยังเป็นสารหล่อลื่นทั้งภายในและภายนอกในกระบวนการขึ้นรูปแบบฉีด

รายละเอียดเพิ่มเติม

POLIMAXX PP ไออาร์พีซีเป็นผู้ผลิตทั้งประเภท PP Homopolymer, Impact Copolymer ที่เพิ่มคุณสมบัติการทนแรงกระแทก PP Random Copolymer ที่มีความใสเป็นพิเศษและสุดท้ายคือ PP Thermoplastic Polyolefin (TPO) พอลิโพรไพลีนนิยมนำไปขึ้นรูปชิ้นงานพลาสติกอย่างกว้างขวาง เช่น ภาชนะบรรจุอาหารสำหรับไมโครเวฟ ถุงพลาสติกทนร้อนสำหรับบรรจุอาหาร แผ่นพลาสติก ชิ้นส่วนรถยนต์ เครื่องใช้ไฟฟ้า เฟอร์นิเจอร์ และภาชนะเครื่องใช้ในครัวเรือน เป็นต้น

รายละเอียดเพิ่มเติม

POLIMAXX PP Compound เป็นอีกทางเลือกหนึ่งของ POLIMAXX Solution ที่นำเสนอความสะดวกในการใช้งานให้กับลูกค้าด้วยการทำ PP Compound ไม่ว่าจะเป็นการทำ Color Matching หรือการผสมสารเติมแต่ง (Fibre-reinforced, talcum) เพื่อปรับปรุงผลิตภัณฑ์ PP ให้ตรงตามความต้องการของลูกค้า

รายละเอียดเพิ่มเติม

POLIMAXX PS (GPPS/HIPS) แบ่งเป็น 2 ประเภท ได้แก่ General Purpose Polystyrene (GPPS) มีคุณสมบัติเด่นในเรื่องความใส มีความทรงรูปสูง ขึ้นรูปเป็นชิ้นงานได้ง่าย นิยมนำไปผลิตบรรจุภัณฑ์ที่เน้นความใส ชิ้นส่วนอุปกรณ์ไฟฟ้า ตลับเทป กล่องซีดี เครื่องใช้ภายในบ้าน รวมทั้งกล่องโฟม ถาดโฟมบรรจุอาหาร เป็นต้น High Impact Polystyrene (HIPS) มีคุณสมบัติเด่นในเรื่องการทนแรงกระแทกสูง และขึ้นรูปง่าย นิยมนำไปผลิตชิ้นส่วนอุปกรณ์ไฟฟ้า กรอบทีวี เครื่องปรับอากาศ กรอบคอมพิวเตอร์ ของเด็กเล่น สุขภัณฑ์ อุปกรณ์เครื่องใช้สำนักงาน แก้ว ถาดบรรจุอาหาร เป็นต้น

รายละเอียดเพิ่มเติม

POLIMAXX PS Compound is an alternative option for providing customer solutions by in-house compound offering the benefit to the customer, IRPC able to do color compound (Color Matching).

รายละเอียดเพิ่มเติม

POLIMAXX UHMWPEE เป็นพลาสติกวิศวกรรม ที่มีความหนาแน่นของโมเลกุลสูงกว่าพอลิเอทิลีนทั่วไปถึง 10เท่า มีลักษณะเป็นผง สามารถขึ้นรูปได้หลากหลายวิธี มีความทนทานต่อการสึกหรอ ทนทานต่อแรงกระแทกและเสียดสีสูงมาก ปัจจุบันนำมาใช้ในงาน อุตสาหกรรมหลากหลาย เช่น สายพานลำเลียง ลูกล้อ เฟือง อะไหล่และชิ้นส่วนของลิฟท์ ตลับลูกปืน และแผ่นกั้นแบตเตอรี่ (Battery Separator) หรือจะเป็นงานเส้นใยที่ต้องการความเหนียว ทนทานแข็งแรง เช่น เสื้อเกราะกันกระสุน เชือกสำหรับกีฬาปีนเขา พาราชูต เป็นต้น

รายละเอียดเพิ่มเติม